OPENING TIMES

ADDRESS

History of Bricks

OAK TREE FARM

DUNBRIDGE LANE

AWBRIDGE ROMSEY

SO51 0GQ

COPYRIGHT© WWW.ROMSEYRECLAMATION.COM 2024 ALL RIGHTS RESERVED: HOSTED BY AH MARKETING

OPEN 8 TILL 4.00PM

MON TO FRIDAY

8.15 TILL 12 NOON SATURDAYS

CLOSED SUNDAYS

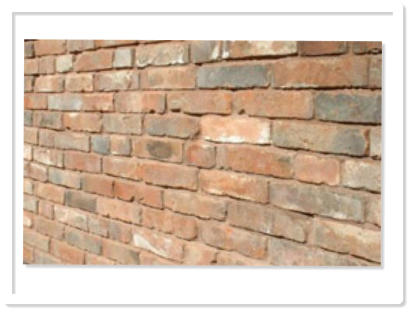

The handmade bricks are more expensive and are typically older and with much more character to them, they have a rough-textured

surface and are lighter and softer than machinemade bricks.

There are myriad descriptions of a handmade brick, the common ones are Soft reds/Soft oranges (the common colours of course),

crease faced bricks, red rubbers (so called because the softness of the surface allows a pattern to be `rubbed` in using a hand file or

special tool, popular in the Victorian era but now almost obsolete)

Reclaimed bricks are usually divided simply into two kinds, Handmade and Machinemade.

They are also available in many colours; you can buy red, yellow, orange, blue, purple, brown, white, and black bricks in both hand

and machine made, although by far the most common are Reds and Oranges, and every imaginable shade in between the two.

Machinemade bricks are harder and heavier than handmades, and the surface is often smooth and shiny, although this is not alway

the case. The machinemade bricks are most commonly also known as `Wire-cuts` because a lot of them have fine, close lines scored

along both wide faces which are from where they were made:

A wire much like a cheese wire was used to cut the clay from the top and bottom of a brick mould, see below for a few

machinemades. Note: not all machinemade bricks have this it is only one, albeit common, method that was used.

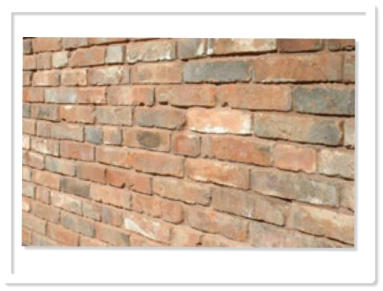

The biggest challenge when buying or selling bricks is matching them up to existing work, if you are building extensions or

adjoining walls of any kind, or if you just want to keep the new building in keeping with the appearance and atmosphere of

structures already in place what you must do, if possible, is get a sample or 2 from the existing brickwork and bring it in to our yard

and match it up to our stock.

Another speciality brick that we always try to stock is the `Tudor brick`, these

are thinner than normal at 2" to 2.25" thick, and are usually used to build

fireplaces.

They are not usually quite as old as the tudor period, but are amongst the oldest

bricks available, usually 100-200 years old or even more.

There are various other brick types that are fairly commonly known, although

are used far less often due to the area they come from or simply their cost and

speciality of application. For example, you can get some Machinemade bricks

known as 18-Hole Bridgewaters

Which are very hard and have 18 holes

in them much like the common

engineering brick.

There are many ways to distinguish Handmades from Machinemades, and it is a case of

seeing and knowing straight away to the expert eye, the most common mistake that people

make is that any brick with a `frog` is a machinemade. The frog is the indentation found in

most bricks, often in the shape of an elongated pyramid inverted in the top of the brick, in

other words `cut-out` of the brick.

The brief recent history of bricks in the UK explains the most common problem we face

with using them:

Before industrialisation really took hold in this country, every town in every part of the

UK would have had their own brickworks, or brickmaker.

In the mid-victorian era when some of these brickmakers became more strongly

established using the new machines they had access to, some became the major supplier

of bricks and indeed tiles in their area, and many of them continue today, or were at least

making bricks in the same style until the mid 20th Century.

The problem is now this: all these brickmakers, successful or not, made different bricks.

The various areas of the UK offer different types of clay in any case, but within these areas different methods were used, and

different people approached those methods in their own way,

“PLEASE BRING

WELLIES”

E&OE All prices are subject to change at any time

Romsey Reclamation Ltd is a limited company registered in England& wales no 3567084

Registered office Highland House, Mayflower Cl, Chandler's Ford, Eastleigh SO53 4AR

- BRICKS RECLAIMED

- BRICKS NEW

- COPPING BRICKS & BRICK SPECIALS

- CHIMNEY POTS

- CRASH BARRIERS

- DOORS RECLAIMED

- FIREPLACES

- FLINT STONES

- GALVANISED ROOFING SHEETS

- GARDEN BENCHES

- GARDEN FURNITURE

- INTERNAL FURNITURE

- GATES

- GRANITE SETS & COBBLES

- HOW TO BUILD A WORKSHOP

- OAK FIREPLACE BEAMS

- OAK TIMBER SERVICES

- OAK FLOORING

- OLD AGRICULTURE FARMING EQUIPMENT

- WOODEN FLOORBOARDS RECLAIMED

- PLYWOOD SHEETS

- POST BOXES

- REDLAND DELTA ROOF TILES

- ROOF SLATES RECLAIMED

- ROOF TILES RECLAIMED

- FINIALS & RIDGES

- RADIATORS CAST IRON

- SCAFFOLD BOARDS

- SCAFFOLD POLES

- SIGNS

- TELEGRAPH POLES

- TIMBER RECLAIMED

- TREATED TIMBER

- TROUGHS

- WALLING STONES

ADDRESS

OAK TREE FARM

DUNBRIDGE LANE

AWBRIDGE

ROMSEY

SO51 0GQ

CONTACT

Phone: 01794 342 252

Fax: 01794 342 221

History of Bricks

- HOME

- PRODUCTS

- BRICKS RECLAIMED

- BRICKS NEW

- CAST IRON RADIATORS

- COPPING BRICKS & BRICK SPECIALS

- CHIMNEY POTS

- CRASH BARRIERS

- DOORS RECLAIMED

- FIREPLACES

- FLINT STONES

- GALVANISED ROOFING SHEETS

- GARDEN BENCHES

- GARDEN FURNITURE

- GATES

- GRANITE STES & COBBLES

- HOW TO BUILD A WORKSHOP

- INTERNAL FURNITURE

- OAK FIREPLACE BEAMS

- OAK TIMBER SERVICES

- OAK FLOORING

- OLD AGRICULTURE FARMING EQUIPMENT

- WOODEN FLOORBOARDS RECLAIMED

- PLYWOOD SHEETS

- POST BOXES

- RADIATORS CAST IRON

- REDLAND DELTA ROOF TILES

- ROOF SLATES RECLAIMED

- ROOF TILES RECLAIMED

- FINIALS & RIDGES

- SCAFFOLD BOARDS

- SIGNS

- TELEGRAPH POLES

- TIMBER RECLAIMED

- TREATED TIMBER

- TROUGHS

- WALLING STONES

- CONTACT US

- DELIVERY

- FIND US

- SLEEPERS

- SCAFFOLD BOARDS

- OAK FIREPLACE BEAMS

- PAVING CENTRE

- LATEST ARRIVALS

- UNUSUAL GIFT IDEAS

COPYRIGHT© WWW.ROMSEYRECLAMATION.COM 2022

ALL RIGHTS RESERVED: HOSTED BY AH MARKETING

Open 8am till 4.00pm Monday - Friday

8.15am till 12 noon Saturdays

Closed Sundays

The handmade bricks are more

expensive and are typically older and

with much more character to them, they

have a rough-textured surface and are

lighter and softer than machinemade

bricks.

There are myriad descriptions of a

handmade brick, the common ones are

Soft reds/Soft oranges (the common

colours of course), crease faced bricks,

red rubbers (so called because the

softness of the surface allows a pattern

to be `rubbed` in using a hand file or

special tool, popular in the Victorian era

but now almost obsolete)

Reclaimed bricks are usually divided

simply into two kinds, Handmade and

Machinemade.

They are also available in many colours;

you can buy red, yellow, orange, blue,

purple, brown, white, and black bricks in

both hand and machine made, although

by far the most common are Reds and

Oranges, and every imaginable shade in

between the two.

Machinemade bricks are harder and

heavier than handmades, and the surface

is often smooth and shiny, although this is

not alway the case. The machinemade

bricks are most commonly also known as

`Wire-cuts` because a lot of them have

fine, close lines scored along both wide

faces which are from where they were

made:

A wire much like a cheese wire was used

to cut the clay from the top and bottom of

a brick mould, see below for a few

machinemades. Note: not all

machinemade bricks have this it is only

one, albeit common, method that was

used.

The biggest challenge when buying or

selling bricks is matching them up to

existing work, if you are building

extensions or adjoining walls of any kind,

or if you just want to keep the new

building in keeping with the appearance

and atmosphere of structures already in

place what you must do, if possible, is get

a sample or 2 from the existing brickwork

and bring it in to our yard and match it up

to our stock.

Another speciality brick that we always

try to stock is the `Tudor brick`, these are

thinner than normal at 2" to 2.25" thick,

and are usually used to build fireplaces.

They are not usually quite as old as the

tudor period, but are amongst the oldest

bricks available, usually 100-200 years

old or even more.

There are various other brick types that are

fairly commonly known, although are used

far less often due to the area they come

from or simply their cost and speciality of

application. For example, you can get

some Machinemade bricks known as 18-

Hole Bridgewaters

There are many ways to distinguish

Handmades from Machinemades, and it

is a case of seeing and knowing straight

away to the expert eye, the most

common mistake that people make is

that any brick with a `frog` is a

machinemade. The frog is the

indentation found in most bricks, often in

the shape of an elongated pyramid

inverted in the top of the brick, in other

words `cut-out` of the brick.

The brief recent history of bricks in the

UK explains the most common problem

we face with using them:

Before industrialisation really took hold

in this country, every town in every part

of the UK would have had their own

brickworks, or brickmaker.

In the mid-victorian era when some of

these brickmakers became more

strongly established using the new

machines they had access to, some

became the major supplier of bricks

and indeed tiles in their area, and

many of them continue today, or were

at least making bricks in the same

style until the mid 20th Century.

The problem is now this: all these

brickmakers, successful or not, made

different bricks

The various areas of the UK offer different

types of clay in any case, but within these

areas different methods were used, and

different people approached those

methods in their own way,

info@romseyreclamation.com

E&OE All prices are subject to change at any time

Romsey Reclamation Ltd is a limited company

registered in England& wales no 3567084

Registered office Highland House, Mayflower Cl,

Chandler's Ford, Eastleigh SO53 4AR